An Insider Guide to Five BYU Labs

By Amanda K. Fronk (BA ’10, MA ’14) in the Spring 2020 Issue

Photography by Bradley H. Slade (BFA ’94)

One Eyring Science Center (ESC) lab features an eroding canyon in miniature—where geology students learn from the power of water. In a low-lit room a few doors down, an intricate arrangement of mirrors turns laser beams into a web of light. In a room farther down still, microphones sit submerged in a 12-foot-long tub of water used to refine sonar technology. And that’s just in the ESC.

Around campus, laboratories are abuzz with questions: How can we reduce coal-burning emissions? Students are lighting up possible solutions in a coal reactor they built in the Engineering Research Laboratory. How can we make protein-rich grains easier to produce? Rows of purple-hued quinoa and amaranth in BYU’s greenhouse may hold answers. How do we get people to pay attention to news articles? Eye-tracking software in the BioComms Lab is providing perspective.

From 3D printing to virtual reality to geospatial mapping and more, professors and students are hunkering down in labs across campus to add understanding at the edges of human knowledge. Step inside five cool labs here.

Self-Driving Car Lab

Electrical and computer engineering professor D. J. Lee’s lab in the Engineering Building basement houses five foot-long cars that drive themselves thanks to “brains” provided by student programmers.

• Cameras (see 1 above) detect stoplight color and distance from objects (like other vehicles and toy pedestrians). Programming the mini-cars teaches students about 70 percent of the know-how they need to develop life-size versions.

• Full-size vehicles use GPS, but the cars in Lee’s lab, located in a basement, are guided by a quasi-GPS system that Lee developed to map his miniature city—dubbed “Leehi” by his students. “This is so much fun. I don’t think I need to be paid to do this,” says Lee.

• The final exam: All five cars (see 2 above) navigate through the Leehi streets simultaneously using only student-created algorithms. Run a red light or veer outside the lanes and lose points.

A Salty Solution

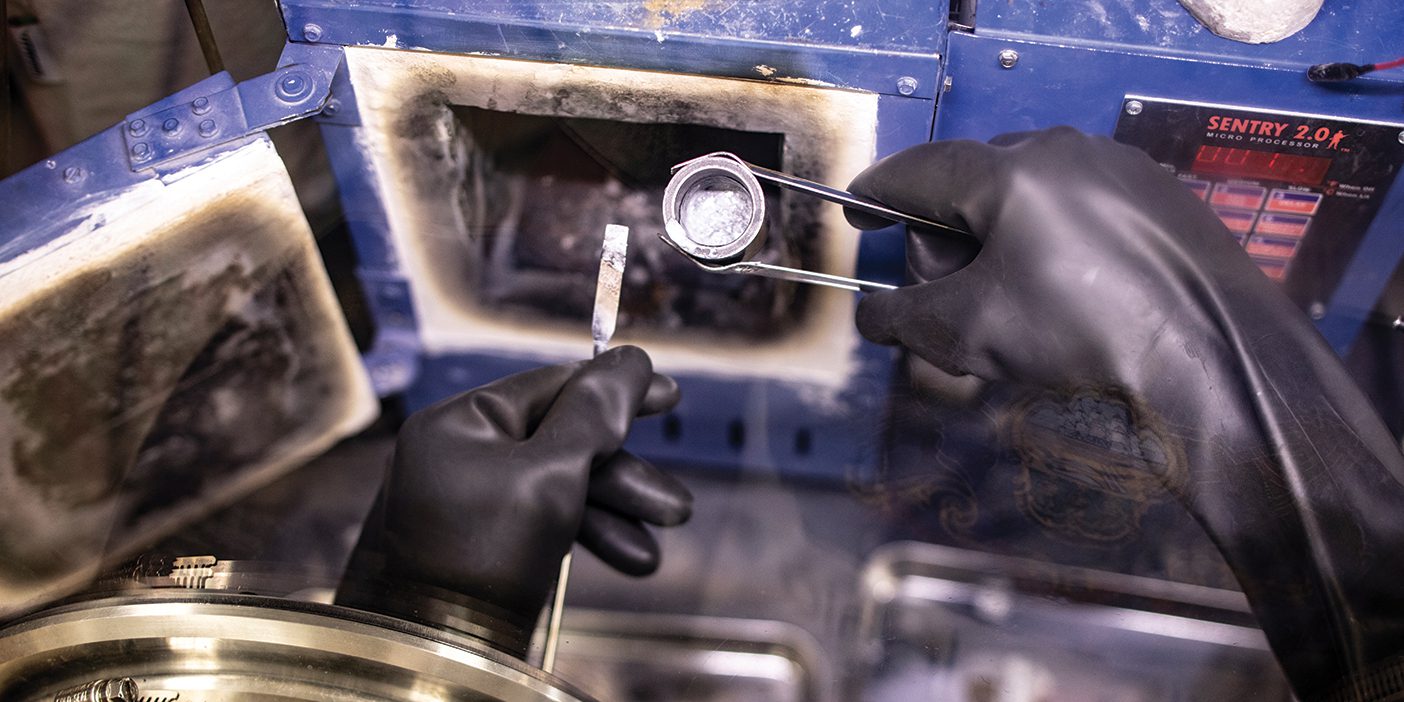

Molten Salt Reactor

Want to make nuclear energy cleaner? Just add salt. Chemical-engineering professor Matthew J. Memmott (BS ’05) combines molten salt with uranium in his lab to produce energy that is cheaper, safer, and cleaner. Traditional nuclear energy traps uranium within a metal fuel rod, where it is blasted with neutrons to induce fissions. Instead of a fuel rod, Memmott uses molten salt, which chemically traps the dissolved uranium and subsequent fission products.

• When built, BYU’s 2 x 2–foot reactor will produce 15 Megawatts of energy—enough to power nearly 1,000 U.S. homes.

• Memmott uses uranium derived from thorium, which does not produce long-lasting radioactive isotopes. The process is the first large-scale power that doesn’t have gaseous pollution or nuclear waste.

• “We turn trash into treasure [with] this unique nuclear reactor,” says Memmott. Byproducts of the molten salt reactor are reusable and valuable, like the medical isotope molybdenum-99 (valued at $30 million per gram!) and precious or even rare earth metals like gold, europium, and palladium.

• The molten salt reactor naturally cools down if the temperature gets too high, making costly safety systems unneeded and preventing disasters like the Fukushima meltdown.

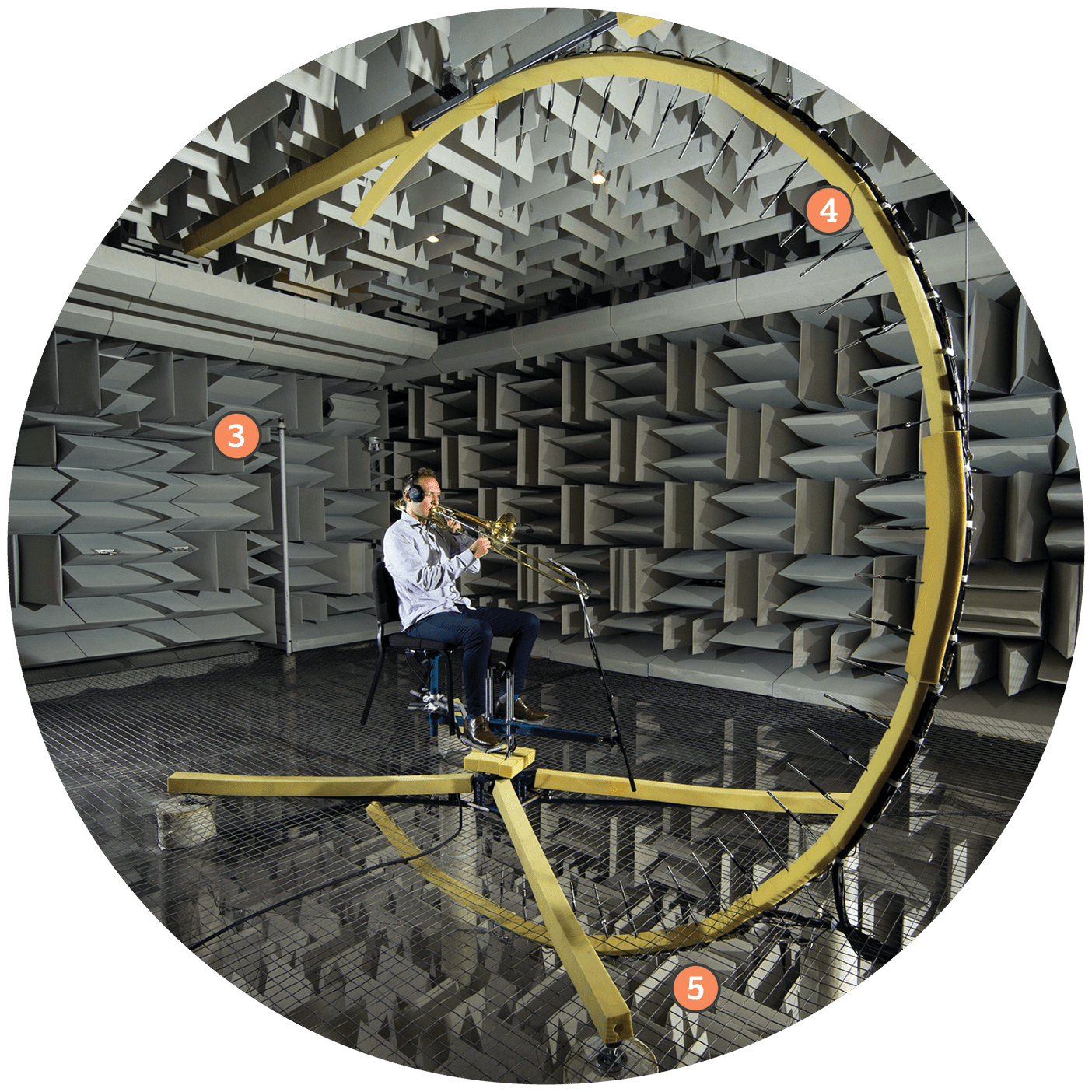

Of Sounds and Silence

Anechoic Chamber

Your heartbeat becomes a constant drum in BYU’s anechoic chamber as your ears adapt to the staggering silence. The quietest room on campus, the anechoic chamber (along with its loud twin, the reverberation chamber) is where BYU acoustics researchers study the intricacies of sound.

• The room is anechoic down to about 80 Hz, close to the lowest notes on a string bass. Because their wavelengths are longer than the length of the wedges’ angles, lower-frequency sound waves do not get trapped.

• The angled wedges (see 3 above) capture sound waves, muting them as they bounce toward the point of the angle.

• This array (see 4 above) supports 37 microphones, picking up the sound produced by trombone performance major Marcus B. Anderson (BM ’16) from various angles.

• The mesh floor (see 5 above), which has held the weight of a grand piano, runs through the middle of the room, with noise-catching wedges below, matching the walls and ceiling.

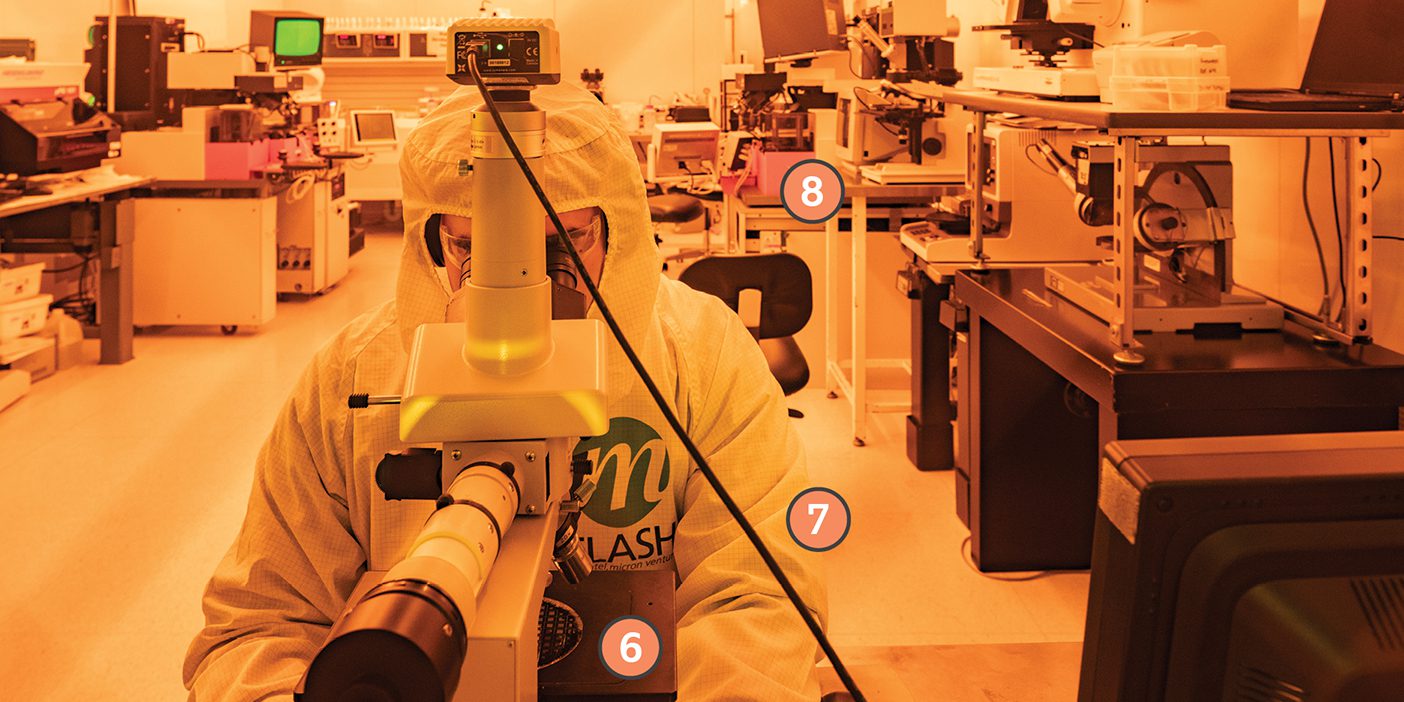

The Cleanest Room on Campus

Integrated Microfabrication Lab

Some engineers build bridges and skyscrapers. At BYU electrical and computer engineers are building complex technologies that are so sensitive a single piece of dust or even the wrong color of light could ruin the entire construction. A special facility in the Clyde Building keeps everything under control.

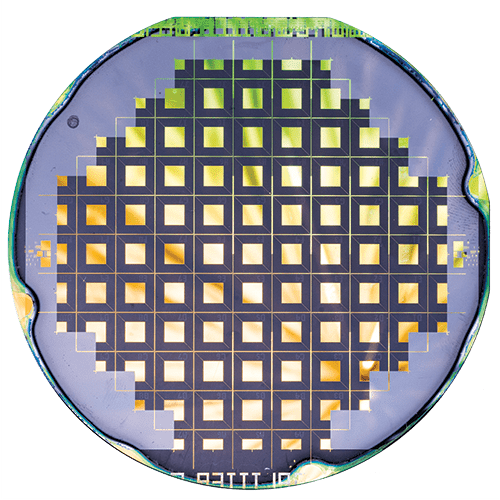

• The first step to manufacturing microscale technology, like computer-chip transistors and carbon nanotubes, is adding layers of metals or compounds to a wafer (see 6 above). The layers can be as thin as 10 nanometers—the equivalent of about 20 silicon atoms side by side.

• The suits (see 7 above) and the clean room’s filtration system eliminate most dust, leaving only about 10 particles per cubic foot—compared to millions of particles in each cubic foot of regular air.

• Microscale printing involves ultraviolet lithography (see 8 above), which creates patterns used for etching away part of the layered wafer, leaving conductive pathways. “It’s crazy because my eyes can’t see it, but I can build it,” says electrical engineering junior Jared G. Marchant (’21), about the minuscule structures he fabricates in the clean room.

• The chemicals used in lithography are sensitive to blue, purple, and ultraviolet light—frequencies all found in white light. This room uses orange instead.

• The microchips in your computer or smartphone feature billions of tiny transistors. BYU student and faculty researchers usually create a single element or nanostructures not found in your traditional computer chip, like microfluidic chips, used in medical diagnostics, that use tiny channels to guide liquids.

Patients You Can’t Harm

Mary Jane Rawlinson Geertsen Nursing Learning Center

If the Kimball Tower basement feels like a hospital, that’s on purpose. But the only patients getting treatment here are 25 high-tech manikins capable of taking on hundreds of maladies.

• Mr. Smith (see 9 above) has pupils that dilate, a palpable pulse, and a chest that rises and falls with each “breath.” He can go into cardiac arrest or have respiratory issues or gastrointestinal bleeds. It’s up to nursing students to diagnose the problem and administer the right treatment.

• Unlike at many universities, BYU’s College of Nursing doesn’t charge students for every cotton swab, syringe, catheter, or other item they use (see 10 above). Students can practice techniques as much as needed in the center’s walk-in lab. “There are a lot of things that we obviously can’t practice on each other or our patients,” says senior Katie C. McCreadie (’20). The NLC gives us “the chance to make mistakes when it isn’t critical.”

• The NLC is one of the first nursing labs in the nation to incorporate electronic health records. Nursing students may work with the same patient over several weeks, keeping digital notes to inform ongoing treatment.

Feedback: Send comments on this article to magazine@byu.edu.