Trash Talk

Trash Talk

When it comes to cleaning up energy and the environment, one man’s waste heap is another man’s treasure.

By Jacob F. Frandsen (BA ’09) in the Summer 2012 Issue

Illustrations by Jude Buffman

Professor Jaron C. Hansen has always had a soft spot for filth. Call it fate: on the day Jaron was born, his father, Conly, built his first anaerobic digester—a garbage-gobbling machine that uses bacteria to break down trash, sewage, and manure. Now, decades later, Conly is still improving his digester and Jaron is a BYU chemistry professor researching sources of clean energy, and he just can’t keep his mind out of the gutter. Or the sewer. Or the landfill.

“Where most people see trash, I see an energy source,” says Hansen. That’s because he’s improving a process that turns the foul stuff clogging earth’s landfills, sewers, and animal farms into clean natural gas that can power generators and automobiles. “As long as you’ve got garbage, you’ve got energy,” he says. “We’re literally taking waste—something that gets flushed down the toilet—and converting it into something good.”

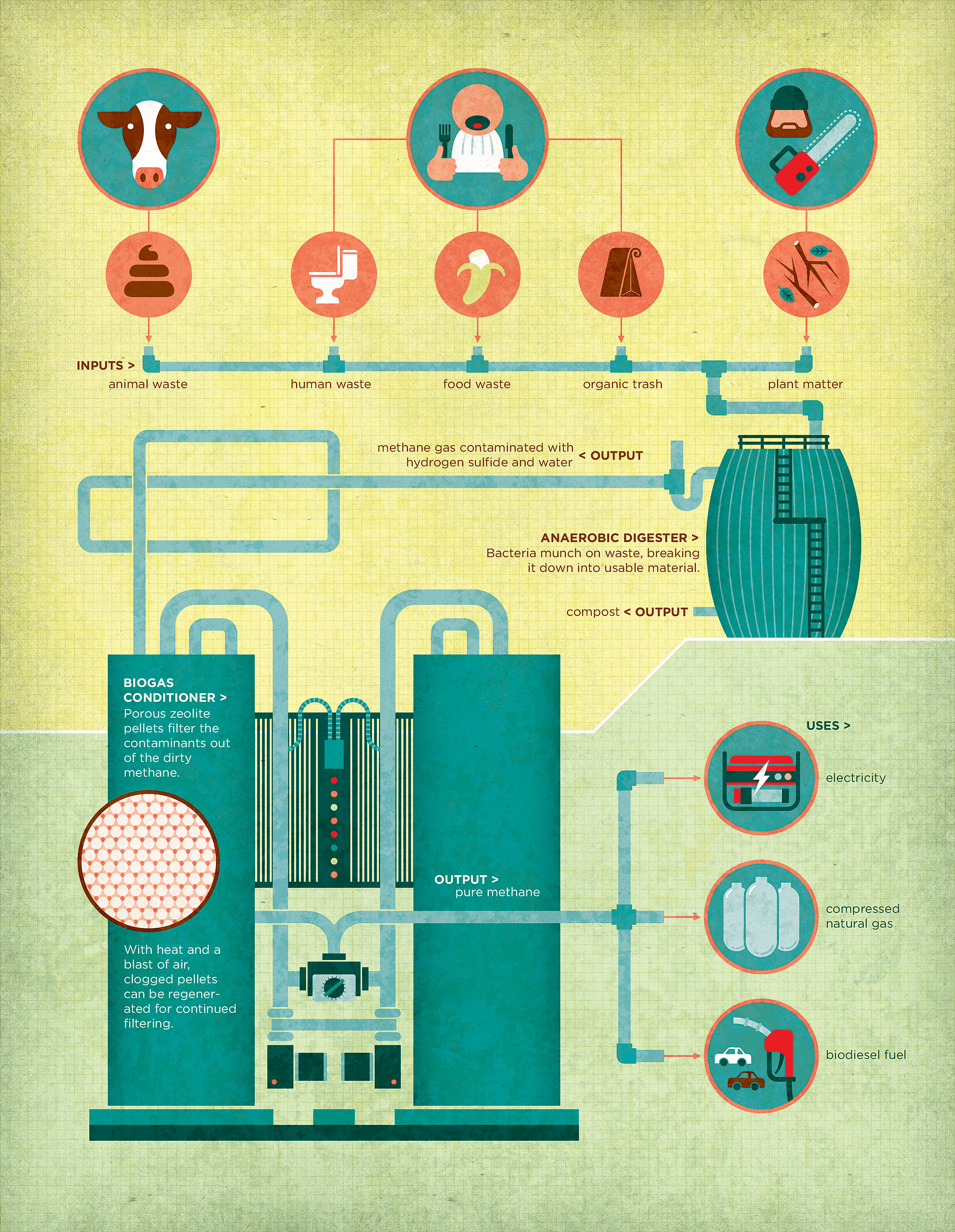

This garbage-to-gas magic happens on a microscopic level in anaerobic digestion. The process feeds special bacteria loads of organic material (think banana peels and cow pies) that then belch out biogas, a rich source of energy that Hansen says is slipping through our fingers. Sewage-treatment plants, for example, enlist bacteria to feast on a soup of solid waste and water in the last stage of the treatment process. But the resulting biogas is often simply flared off because it’s “dirty.” Although it’s mostly methane, it’s contaminated with corrosive hydrogen sulfide and water vapor that would destroy any engine it’s put in.

The gas can be cleaned up using pricey biogas conditioners, which may cost as much as half a million dollars. But Hansen and his research partner, emeritus BYU professor Lee D. Hansen (BS ’62, PhD ’65) (no relation), have patented a new conditioner that can be hooked up to any digester and purify the dirty gas for about an eighth of the cost. The scrubbed gas can then be compressed to power generators and engines or even be turned into liquid biodiesel. Though it’s still pricier to produce biogas than fossil fuels, “it now makes economic sense to use anaerobic digestion to make renewable energy,” Jaron Hansen says. And it’s much friendlier for the environment.

Hansen is now working with his dad’s anaerobic digester company, Andigen, to start marketing and distributing the conditioner. Jacob D. Dustin (MS ’77, PhD ’78), former Andigen president, says, “We’re encouraged [by this new conditioner] because it’s much cheaper to install and operate, and it’s regenerable.”

One of Hansen’s biogas conditioners stands near a corner of his Benson Building lab. About the size of a Smart car tipped onto its bumper, the machine is all hoses and pipes and cylinders. But Hansen makes things simple. “You put dirty gas in the inlet,” he says. Then, pointing to a jutting length of PVC pipe, he adds, “And the clean gas comes right out of here.” Between the inlet and outlet, the gas passes through a large cylinder filled with the conditioner’s patented secret weapon—tiny pellets of zeolite, a super-porous mineral that might be mistaken for grains of lawn fertilizer. The zeolite “acts like a little molecular sponge,” absorbing hydrogen sulfide and other contaminants as the gas passes through. When the zeolite gets clogged with molecular gunk, it can simply be heated up and blasted with air, which “wrings out the sponge,” says Hansen. “Then the zeolite’s ready to be loaded up again.” By comparison, other conditioning methods use expensive chemicals that must be replaced after they’re used.

“When I look out and see some of the waste piles that we generate, it causes some sadness for me, because I think we could do better.” —Jaron Hansen

This particular conditioner unit sitting in Hansen’s lab is bound for Provo City’s wastewater treatment plant, and as Hansen fusses over a loose wire, he looks like a proud father preparing to send a kid to the first day on the job. “Provo City’s making 50 to 100 cubic feet [of biogas] per minute,” he says, patting the conditioner’s cold metal tank. “That’s what this big boy’s for.”

Half a world away, two of Hansen’s other “big boys” are already hard at work at a dairy farm in Jinshan, China, benefitting not only the farm’s day-to-day operations but the environment as well. The conditioners were installed alongside two three-story anaerobic digesters in April 2011 as part of the Jinshan Clean Energy Project, a collaboration between several Utah companies and Honde Environmental, a Chinese company that handles environmental-cleanup projects. “Up to this point [the dairy] had been relying on composting,” says Hansen, “taking the waste coming out of the back end of the cows and putting it in big piles and letting it rot in the sun so everyone can smell it, everyone gets stinked out. And there was nothing really useful being done with this waste.”

Diana Bao, vice president of Honde Environmental, was impressed to see Hansen get his hands dirty as he helped install the conditioners last year. “In my impression, university professors just work in labs or write papers,” Bao says. “Very few scientists can do the real site work.” Shawn Hu, an old friend of BYU and founder of Honde, says, “That is [the] meaning of ‘The World Is Our Campus’: a professor’s innovative idea has gone from classroom to community [and is now] on site, in China.”

Today, the olive-green Jinshan digesters treat 10,000 gallons of manure-water blend every day, which means the dung is no longer flushed into local waterways or allowed to release ozone-harming methane into the atmosphere. The system cleans up odors and reduces the solid waste by well over half, turning it into clean compost.

The resulting biogas is generating valuable electricity. “These guys are desperate for electricity, especially in the rural areas,” says Hansen. “So the fact that we can provide power to everybody at the dairy—and even in the surrounding community—just off the waste they’re generating at the plant is a real plus.”

Closer to home, one of Hansen and Hansen’s conditioners is now operating at the wastewater treatment facility in Logan, Utah. Such sewage treatment facilities are an ideal setting to generate biofuel, thanks to their constant stream of organic waste. “The more people poop, the more electricity we’re going to make,” says Hansen, smiling. “It will just go on and on forever.”

During a visit to the Provo treatment plant, Hansen inspects the location where the conditioner now waiting in his lab will be installed. Pipes of every description crisscross walls, ceilings, and even floors. Spigots and faucets are everywhere as well. Considering the setting, it’s not surprising that each one bears an ominous sign admonishing, “Do Not Drink.” Jutting out of the ground outside, a tall pipe is constantly flaring off the digesters’ gas, giving the appearance of a 30-foot birthday candle. But the eternal biogas flame will soon be blown out as the gas is redirected to Hansen’s conditioner and then transformed into biodiesel to fuel the city’s fleet of vehicles.

Atop one of the facility’s building-sized digesters, Hansen discusses details of the installation with plant manager Mark Ogren. As Ogren lifts the cap of the digester’s chimney-like vent, a blast of methane gas from somewhere deep within the digester is released. Hansen doesn’t recoil. Instead, he leans slightly forward and inhales deeply. “That’s the juice!” he says, gushing with enthusiasm. “That’s the stuff we want!”

It seems that biogas is a fuel that will keep Hansen going for a long time as he and Lee Hansen search for wider applications for their technology. In the works is a patent for a semitrailer containing 20 toilet stalls, all connected to an anaerobic digester, conditioner, and generator. The outfit could be placed in disaster areas cut off from normal utilities, helping dispose of disease-filled human waste and in turn generating electricity and gas to run heaters and stoves.

“We’re always on the hunt for new energy sources,” says Hansen, “whether it be garbage, human waste, animal waste, or algae. We think, man, let’s not just throw it away, let’s not just bury it someplace. Let’s turn it into something useful.”

Hansen believes that turning waste into something useful will change the way we think about garbage. We may even start to see trash as a commodity. “The day is coming here very quickly when you’re not just going to dump everything in a landfill and walk away,” says Hansen. Instead, “landfills will separate out all the recyclables [and] take the organic components and break them down into biogas.”

“When I look out and see some of the waste piles that we generate, it causes some sadness for me, because I think we can do better,” says Hansen. “If we’re going to be wise stewards of this earth, I think we’re obligated to invest in these kinds of technologies.”

Feedback: Send comments on this article to magazine@byu.edu.