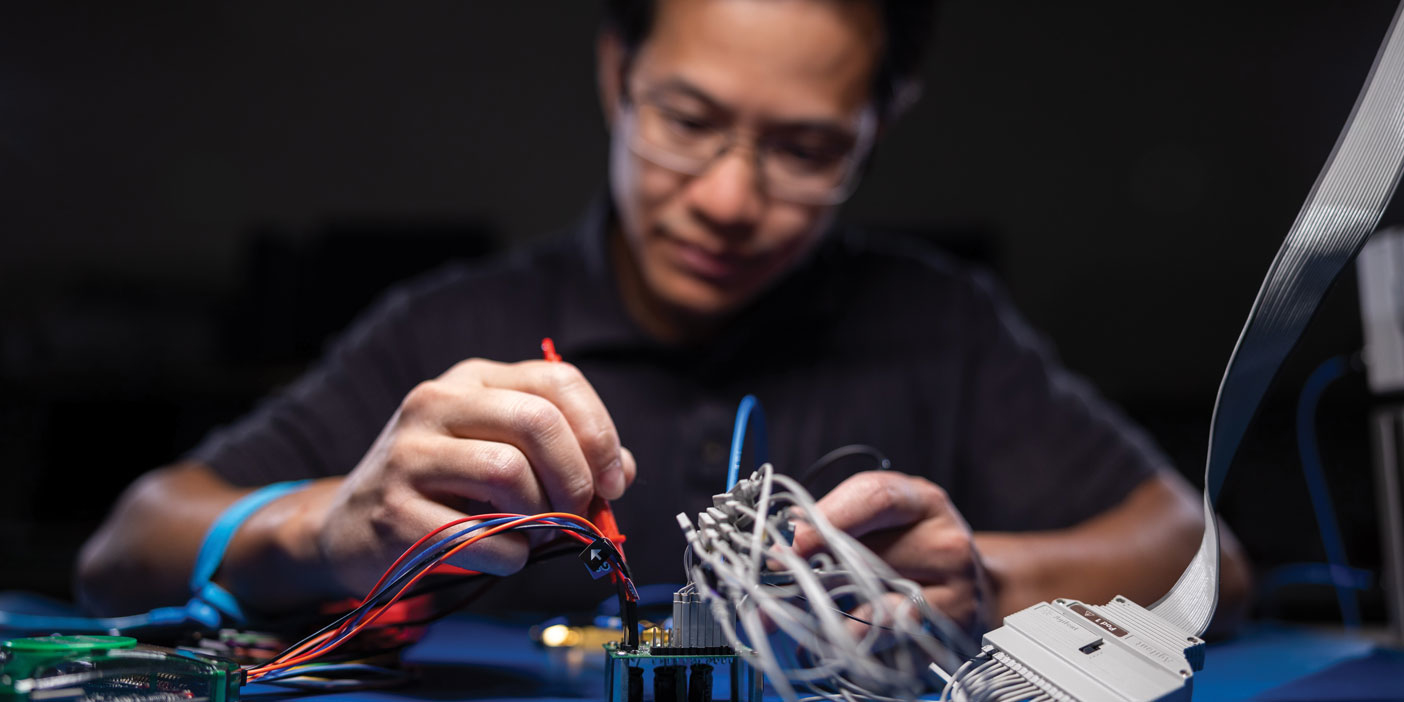

Linton Salmon holds a wafer containing 1,200 of the tiny batteries he helped invent, each one 100 times more powerful than existing microbatteries.

By Grant Madsen

A team of BYU engineers and a Provo-based company have invented a tiny battery that one day may be used to power pumps that regulate insulin flow in diabetics or to run sensors that monitor vital signs in trauma victims.

While microbatteries are not new to the engineering industry, this recent microbattery is unprecedented in its size and power. The battery is as thin as a strand of human hair and 100 times as powerful as existing microbatteries.

BYU team leaders Linton Salmon, associate dean of the College of Engineering and Technology, and John Harb, associate professor of chemical engineering, say they achieved these improvements through a new production process.

“Previously, microbatteries have been assembled in a piece-by-piece fashion similar to the building of an automobile,” Salmon says. “We built these microbatteries using the same processes employed to build computer chips–intricate patterning with extremely small dimensions and extremely pure materials. We hope to achieve the same kind of performance advances in the micropower field that have occurred in the computer industry.”

Salmon presented the results of his team’s research at the Solid-State and Actuator Workshop in Hilton Head, S.C., in June.

“What Salmon’s research does is allow producers to simplify the circuitry in heretofore complex systems,” says Robert Huber, professor of electrical engineering at the University of Utah and a member of the workshop’s program committee. The simplification enables engineers to include microbatteries directly in the tiny devices they build.

Such devices are known as microelectromechanical systems, or MEMS. When Salmon was supervising MEMS research for the National Science Foundation in the early 1990s, he noticed that fellow engineers were developing tiny, intricate systems that could be very useful–except for one problem: “Many of them were powered by a D-cell battery,” Salmon recalls. “There’s no point in building a MEMS product if there is no energy source correspondingly small enough to power it.”

When Salmon returned to BYU, he and his colleagues set out to fill that empty niche.

The microbatteries have potential applications in various industries such as automobiles and medicine.

“Vehicles have and are going to have an increasing number of sensors,” says BYU graduate Rodney LaFollette, founder of Bipolar Technologies, the Provo company marketing the microbatteries. “Autos will have sensors to indicate tire wear or the temperature of and wear on the engine. Sensors will map the entire state of the vehicle.”

Information gathered by sensors will be processed by an onboard computer. Knowing the condition of a vehicle will translate into consumer savings, LaFollette says.

“I am personally convinced that microbatteries have tremendous potential for a large number of autonomous sensor applications, including those in the medical field,” Salmon says.

“If you need to implant a sensor into a person’s body, you don’t want connecting wires leaving the body,” he says. “Microbatteries are the answer; they remove the need for wires connecting to power sources or to central control stations.”

“I am excited about all the application possibilities the microbatteries bring with them,” LaFollette says.