What does an engineer-turned-world-famous-YouTuber do after he’s built the world’s largest “Nerf gun”?

Build the world’s smallest, obviously.

“I knew I wanted to use nanotechnology and that I needed to go to the school that was kind of the cutting edge, that led in this field,” says Mark B. Rober (BS ’04), who’s used the mechanical-engineering chops he honed at BYU to captivate hundreds of millions with his engineering feats. Rober sought out his former teacher mechanical-engineering professor Larry L. Howell (BS ’87) to develop history’s tiniest dart launcher.

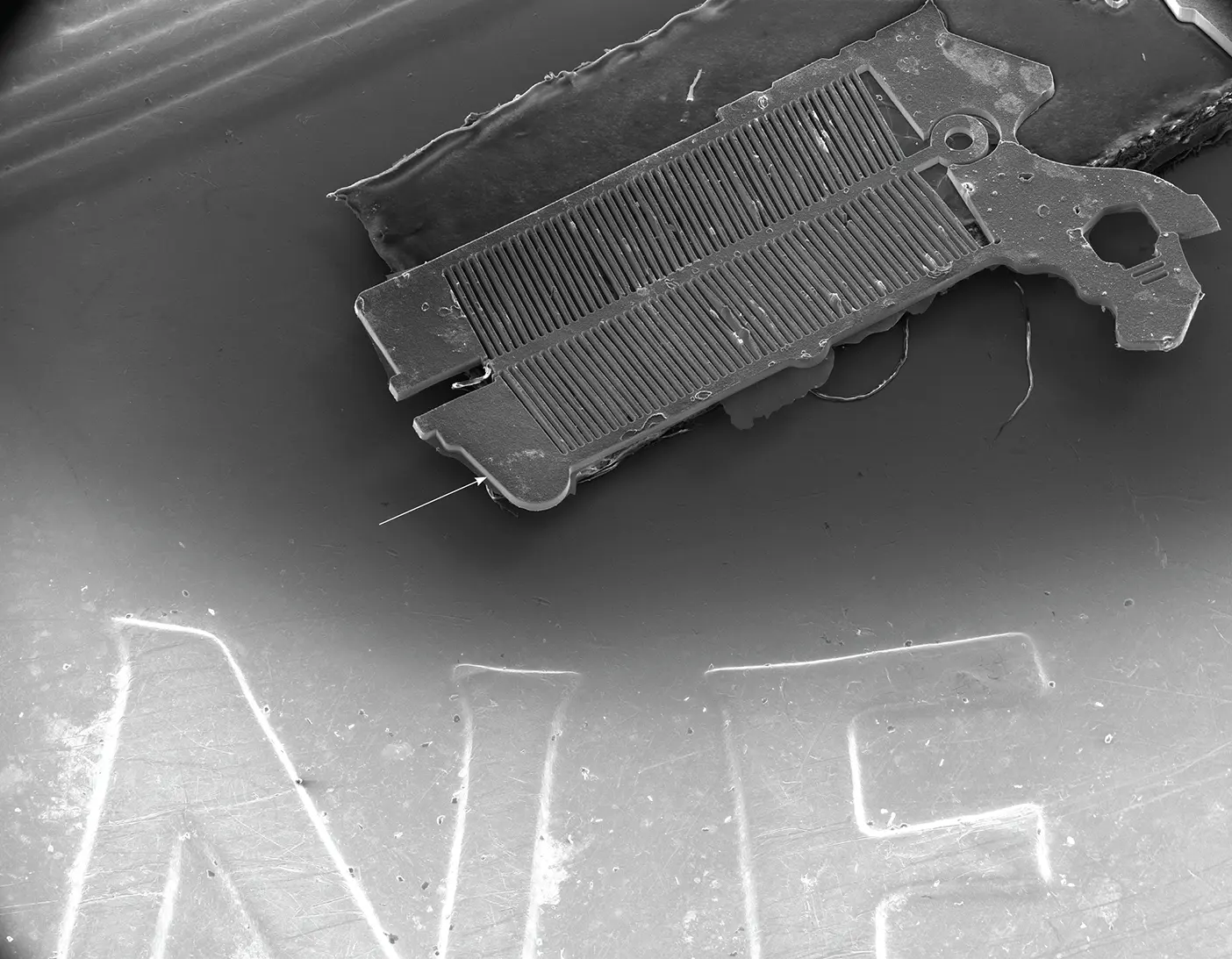

Howell is one of the world’s leading experts in compliant mechanisms. A compliant mechanism is a single component that fulfills the function of hinges and springs by folding and bending like origami. Zoom in to discover the innovations that made this wacky idea a reality.

0.1209 in

The length of the world’s smallest working “Nerf gun”—shown here atop a penny. At 1/100th the size of the original, it’s roughly the size of a fleck of pepper.

1

component is used in the tiny blaster, compared to 87 in the full-size version. “It would be impossible to assemble those tiny mechanical springs and hinges” at the scale of a human hair, Rober says in his video. Instead, the mini gun is made from a compliant mechanism. Applications for compliant mechanisms range from bottle lids to satellites. “Anything that [requires] high precision,” Howell says, “usually uses a compliant mechanism.”

100 Micrometers

The size of the dart. “It was just impossible to get something that was accurate enough to hold it tight enough to fire,” says grad student Bethany M. Parkinson (BS ’22). After hundreds of attempts, and just a week before filming, they discovered how to use a micromanipulator to position the dart.